CASE STUDY

Ryan

Solution Specialist

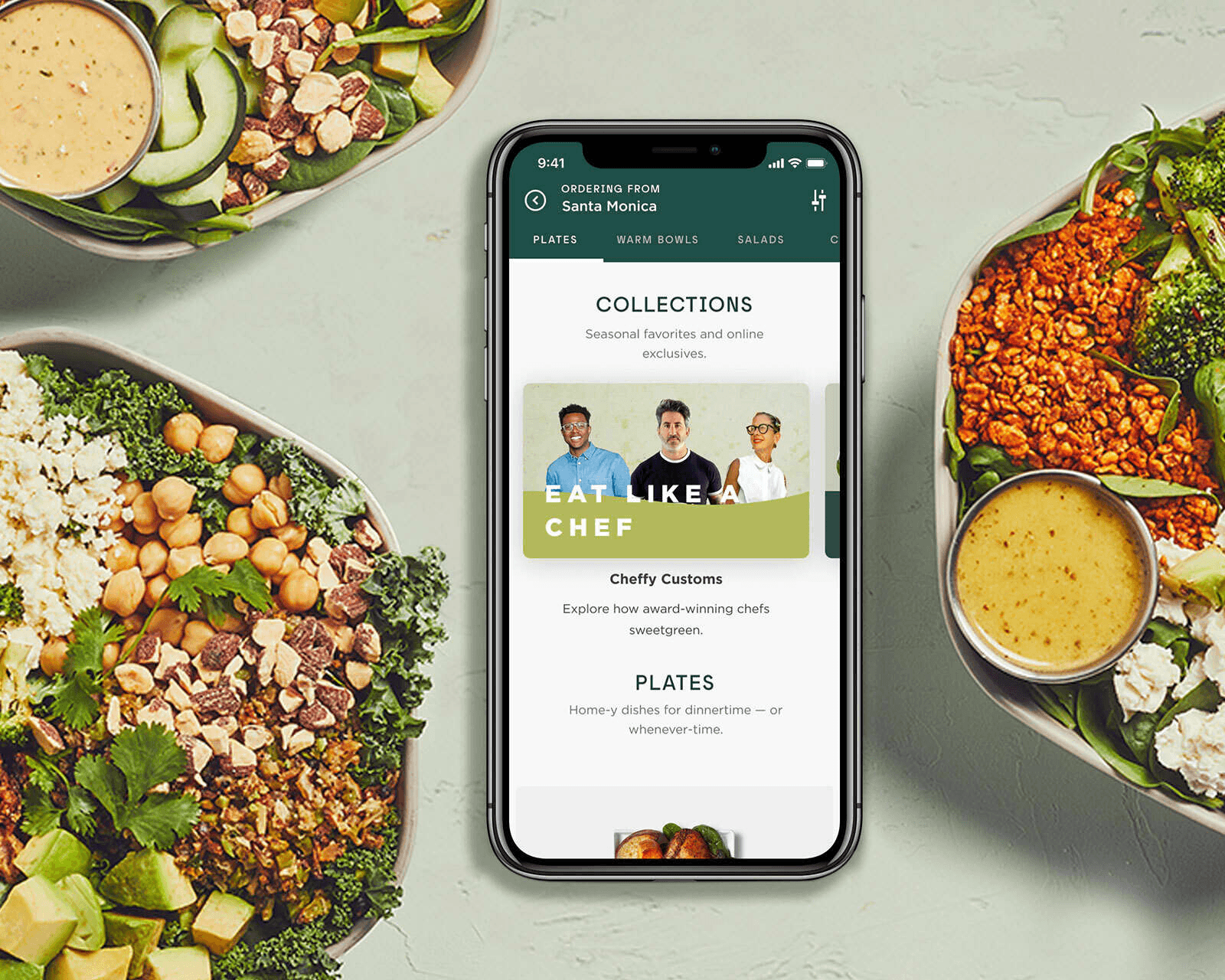

Known for its commitment to sustainability, local sourcing, and high-quality ingredients, Sweetgreen needed a sophisticated technology strategy to maintain these standards while scaling efficiently.

To address these challenges, Sweetgreen invested in custom software solutions, focusing specifically on optimizing its supply chain and inventory management. This case study explores how Sweetgreen used custom technology to streamline its operations, minimize food waste, and ensure ingredient quality across all its locations.

Key challenges faced by Sweetgreen

As Sweetgreen expanded rapidly across the United States, the company encountered several key challenges in managing its supply chain:

Managing inventory across multiple locations: With over 200 brick-and-mortar locations in 13 markets and more than 550 Outposts (pickup-only spots in offices and other facilities), Sweetgreen needed to manage a highly complex, geographically dispersed supply chain efficiently (Nation's Restaurant News).

Sourcing fresh and local ingredients: Sweetgreen’s commitment to locally sourced, sustainable ingredients required a system capable of managing multiple supplier relationships while ensuring that inventory was replenished in a timely and sustainable manner.

Minimizing food waste: The company needed to balance maintaining freshness with minimizing waste, especially given the perishable nature of many of its ingredients.

Ensuring transparency and compliance with sustainability standards: As a brand built around transparency and sustainability, Sweetgreen required a system that allowed it to track its ingredient sourcing, food waste, and supplier performance while maintaining its brand promise.

Sweetgreen's custom solutions for supply chain and inventory management

To tackle these challenges, Sweetgreen developed and implemented a custom software solution focused on improving the transparency, efficiency, and accuracy of its supply chain and inventory processes.

Real-time inventory tracking and predictive ordering: Sweetgreen developed a real-time inventory tracking system that integrated with its Point of Sale (POS) and kitchen management software to provide accurate, up-to-date information on stock levels. This system was built to monitor every ingredient across all locations, ensuring that no restaurant experienced stock shortages while minimizing over-ordering.

Predictive ordering: Using historical data, the system could predict demand for certain ingredients based on trends such as seasonality, location-specific preferences, and time of day. This allowed each location to order just the right amount of ingredients, reducing the risk of waste while ensuring freshness.

Automated replenishment: The software enabled automatic replenishment based on set thresholds, ensuring that locations remained well-stocked without manual intervention from store managers.

.

Supplier integration and performance tracking: Sweetgreen built a supplier management system that integrated directly with its suppliers. This allowed the company to track real-time delivery schedules, ingredient quality, and supplier performance, ensuring that all suppliers met the company’s strict sustainability and freshness standards.

Supplier performance monitoring: The system tracked metrics such as on-time deliveries, ingredient quality, and compliance with sustainability requirements. This allowed Sweetgreen to identify and reward top-performing suppliers while addressing any issues with underperforming vendors.

Local sourcing: The software was designed to support Sweetgreen’s local sourcing model, allowing each location to work with regional suppliers and manage unique supply chains.

Waste reduction through data-driven insights: Sweetgreen’s custom software used data analytics to help reduce food waste. By analyzing past sales data and monitoring current stock levels, the software provided actionable insights to store managers on how to adjust ordering patterns and minimize excess inventory.

Real-time waste tracking: The system tracked ingredient expiration dates and waste generated, providing insights into areas where inventory management could be improved. This helped Sweetgreen further its mission of sustainability by reducing food waste across its network of locations.

Ensuring transparency and sustainability compliance: The custom software also tracked the sustainability of Sweetgreen’s supply chain, providing transparency into ingredient sourcing. By integrating with sustainability metrics, the system allowed the company to communicate its environmental impact to customers.

Sustainability reporting: The software generated reports on ingredient sourcing, carbon footprint, and other sustainability factors, helping Sweetgreen comply with its environmental goals and communicate these efforts to a growing base of environmentally conscious customers.

Results: better operations and consistent ingredient quality

The custom software development initiative yielded several key results for Sweetgreen:

Optimized inventory management: Sweetgreen’s predictive ordering and automated replenishment reduced stock shortages and over-ordering, ensuring that locations always had fresh ingredients without generating excess waste.

Improved supplier relationships and performance: By integrating supplier data into its system, Sweetgreen was able to closely monitor and improve supplier performance, ensuring timely deliveries of high-quality ingredients.

Reduction in food waste: The data-driven insights generated by the custom software enabled Sweetgreen to optimize its ordering patterns, leading to a significant reduction in food waste across its locations.

Increased sustainability compliance: By tracking sustainability metrics in real time, Sweetgreen was able to maintain its commitment to local sourcing and environmentally friendly practices, ensuring transparency with customers and stakeholders.

A tech-driven approach to supply chain management

Sweetgreen’s custom software development strategy for supply chain and inventory management played a critical role in the company’s ability to scale efficiently while maintaining its commitment to quality and sustainability. The implementation of real-time inventory tracking, predictive ordering, and supplier management systems allowed Sweetgreen to optimize its operations and reduce waste, helping the company meet customer demand for fresh, locally sourced ingredients without compromising on its sustainability goals.

As restaurant chains continue to grow, Sweetgreen’s approach provides valuable insights into how custom software can streamline supply chain operations and drive sustainability across multiple locations.

Takeaways for smaller and mid-sized restaurant chains

While Sweetgreen’s tech strategy was designed to handle the complexity of a large-scale operation, smaller and mid-sized restaurant chains can apply several lessons from its experience:

Start small with predictive inventory management: Even smaller chains can benefit from implementing basic inventory management software that uses historical sales data to predict demand. This prevents over-ordering and reduces food waste, while ensuring that key ingredients are always available.

Build supplier relationships with custom tracking: Smaller chains can implement custom supplier management systems that track supplier performance, ensuring timely deliveries and quality control. Even basic systems can provide valuable insights into which suppliers are meeting standards and where improvements can be made.

Focus on sustainability through transparency: While large chains like Sweetgreen have advanced sustainability tracking, smaller chains can start with basic sustainability reporting tools that track sourcing and waste management. This allows smaller chains to communicate their sustainability efforts to customers and build brand loyalty.

Invest in scalable technology: Smaller chains should consider investing in scalable software solutions that can grow as the business expands. Starting with simple, custom solutions allows restaurants to build more complex systems as they scale, avoiding the need for costly overhauls later on.